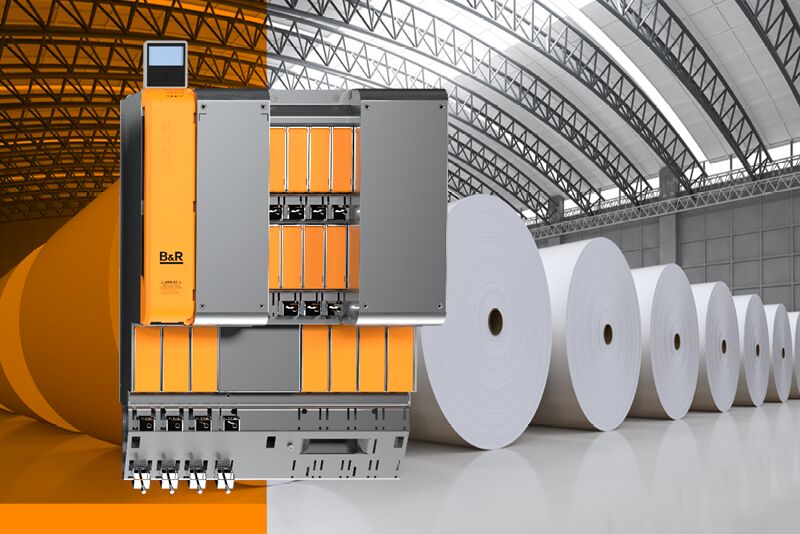

A new era of drive technology

With the new generation of the ACOPOS P3, B&R is setting new standards for performance, compact size and intelligence. The advanced design offers unrivaled power density and precision in an extremely compact format reducing the space required in the control cabinet by up to 50%. Despite 60% more power output and eight times the computing power, the size remains unchanged. The extended series with power outputs up to 80 kW – including space-saving 2-axis modules – gives machine builders maximum scalability. B&R thus fulfills key industry requirements for higher productivity, reduced costs and greater availability.

Extremely compact and powerful

The ACOPOS P3 offers extensive performance enhancements for precise and demanding motion control applications. Depending on the required power – up to 80 kW – it combines up to three axes in a single housing. The result is maximum performance in a minimum amount of space and a significantly optimized control cabinet footprint.

Precise and ultra-fast controller

With a sampling time of just 50 µs, the ACOPOS P3 enables extremely fast and high-precision drive control. It is therefore ideal for particularly demanding applications such as CAM profiles, local PLC tasks directly in the drive (SPTs) or control loops.

Intelligent motion functions

In combination with model-based control and virtual sensors, these functions enable effective vibration and mechanical resonance damping, greater path precision and improved product quality, even at high speeds.

Flexible cooling and global compatibility

Using modular cooling concepts such as air cooling and cold plates, the ACOPOS P3 can be optimally adapted to any installation situation. The system is also compatible with all common power supply systems and can therefore be used worldwide without additional measures.

ACOPOS P3 1-axis 32 kW / 40 kW / 51 kW / 80 kW

The ACOPOS P3 portfolio has been expanded to include new high-power 1-axis modules with power outputs up to 80 kW. With four additional power output classes, the expansion offers outstanding performance, high scalability, compact dimensions and maximum power density in a minimum amount of installation space. This makes them ideal for applications where space in the control cabinet is at a premium.

Specially developed for demanding industrial environments such as plastics processing, the paper industry, metalworking and printing, the new high-power modules are particularly robust and reliable.

- 2x the power scalability: 32/40/64/80 kW

- 25% more power: 80 kW compared to 64 kW

- 60% more power density: 51 kW compared to 32 kW

- 8x the computing power: 50 µs cycle time compared to 400 µs

ACOPOS P3 2-axis 32 kW /40 kW / 64 kW

The new 2-axis version of the ACOPOS P3 combines two axes, each with up to 64 kW, in a single, compact module and reduces the space required in the control cabinet by up to 50%. It offers the highest performance with maximum scalability and doubles the power density in the smallest spaces. It is therefore ideal for modular machine concepts and applications with limited installation space.

- 2x the power scalability: 32/40/64 kW

- 50% less space required: 2 axes in the same base area

- 60% more power density: 2-axis module delivers 80 kW compared to 64 kW

- 8x the computing power with a 25 µs cycle time

ACOPOS P3 1-axis 10-14-18 kW / 2-axis 7-9 kW

With power outputs up to 18 kW and up to 9 kW per axis in dual operation, the ACOPOS P3 is the ideal solution for power-intensive machine modules. A high power density and compact housing provide maximum energy and dynamics with minimum space requirements.

ACOPOS P3 1-axis/2-axis/3-axis 1-4 kW

In the power range from 1 to 4 kW, the ACOPOS P3 impresses with maximum flexibility: It allows multiple axes to be combined in one compact housing. This reduces the wiring effort, saves space in the control cabinet and enables a consistently modular machine architecture.

ACOPOS P3 1-axis 0.7-4 kW

Compact, powerful and precise: The ACOPOS P3 covers power ranges from 0.7 to 4 kW – ideal for applications with mid-range power requirements. Thanks to the space-saving design, the control cabinet can be significantly reduced in size without sacrificing performance or dynamics.

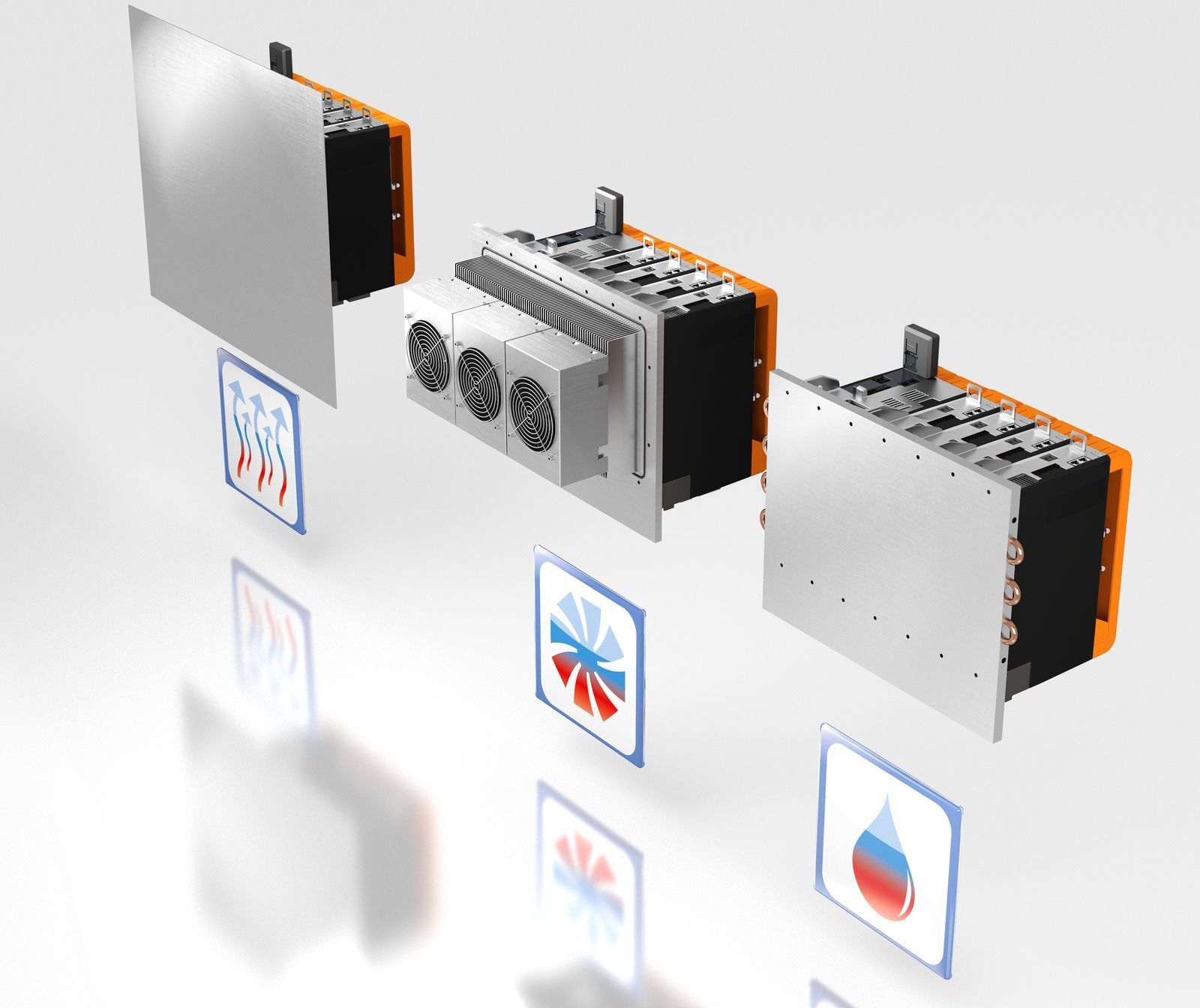

Modular cooling concept for ACOPOS P3

The ACOPOS P3 servo drive is available with pass-through heat sink or cold plate cooling. This reduces the use of fans and air conditioners in the control cabinet or, ideally, eliminates them altogether. The control cabinet size requirements and maintenance costs are reduced. System designers can choose between three cooling variants for the ACOPOS P3:

With conventional wall mounting, heat dissipates via the air inside the control cabinet. This solution is optimal for a small number of axes with low power.

With a large number of axes in all power ranges, pass-through mounting is more suitable. Based on an IP65 pass-through heat sink, the heat loss is dissipated directly into the ambient air outside the control cabinet. The control cabinet itself does not require costly cooling and dust accumulation in the servo drive is reduced.

This method utilizes a water-cooled cold plate. Around 60% of the heat lost from the devices is transferred to the coolant. This type of cooling is suitable for a large number of axes in all power ranges as well as for machine processes that require high peak power over a longer period of time. It requires the machine to have its own cooling circuit.