Integrated safety technology

Integrated safety technology refers to the seamless integration of safety functions into the automation architecture of an industrial system. In contrast to traditional, separate safety solutions, integrated safety enables the shared use of hardware, software and communication infrastructure for standard functions and safety functions.

Core principles

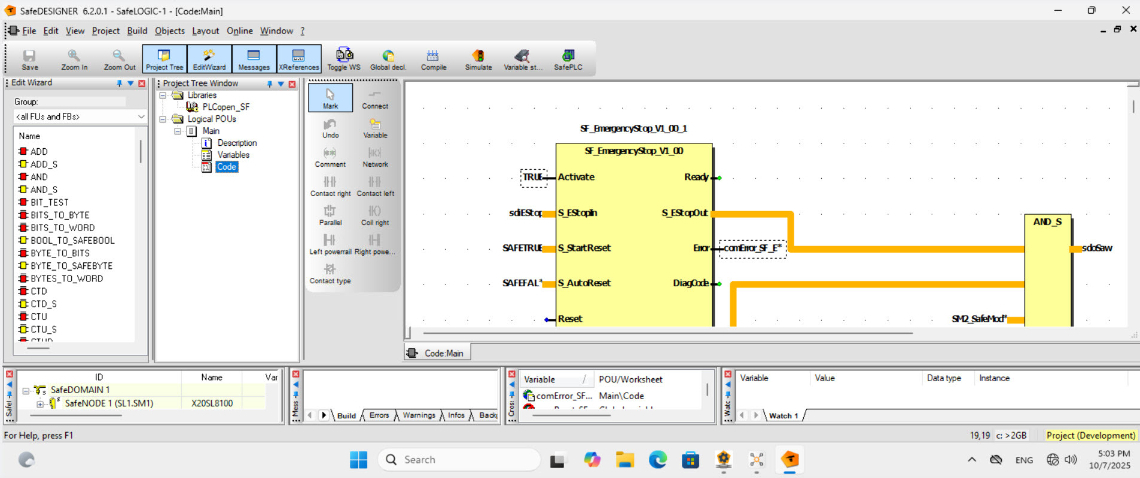

Integration instead of separation

Safety functions are embedded directly in the control systems – no separate safety controller required.

Centralized project planning

Safety logic is created and managed in the same engineering tool as standard automation.

Seamless connectivity

Safe data transfer via standardized protocols such as Safety over Ethernet or PROFIsafe.

Scalability and modularity

Flexible adaptation to different machine and system concepts.

Advantages

Reduced engineering effort

Joint project planning saves time and minimizes sources of error.

Cost effectiveness

Fewer hardware components and less wiring work.

Increased transparency

Uniform diagnostics and HMI for standard and safety functions.

Faster commissioning

End-to-end tools and automated tests speed up the process.

Conclusion

Integrated safety technology is a key concept for modern, efficient and safe automation solutions. It enables a holistic view of functionality and safety – for greater productivity, flexibility and reliability in industrial manufacturing.