The B&R vision system lets machines operate more autonomously and efficiently—producing more, with less downtime and less unnecessary waste. High-performance cameras, intelligent lighting, and powerful software come together as a seamless part of your automation solution, optimizing performance without unnecessary engineering complexity or integration costs.

Patented fieldbus integration puts vision right in the control loop, enabling tight synchronization with motion control and robotics. This helps optimize the performance of high-speed inspection, sorting and handling tasks—where reactions and adjustments need to happen at full production speed.

Your advantages

Discover our vision system

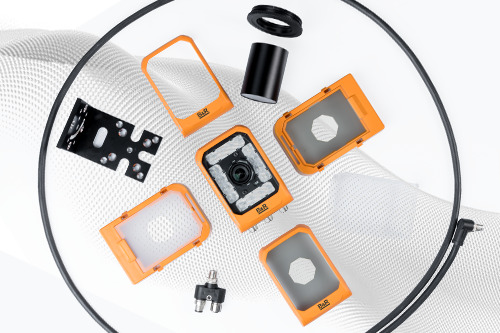

Cameras

B&R cameras combine rule-based and AI vision in a single plug-and-play device.

Lighting

Precision lighting delivers optimal image quality in any environment.

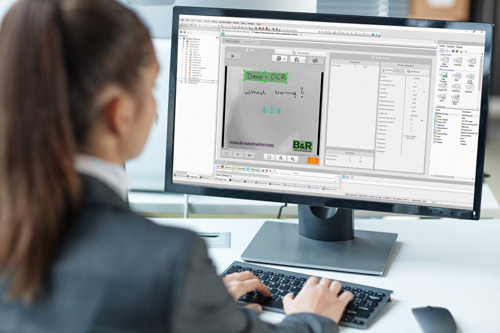

Software

Configure, simulate, and deploy vision functions without extensive coding or vision expertise.

Accessories

All you need for a complete solution, including mounting kits and protective housings.

Synchronization with µs precision

Both the hardware and software in B&R's vision solution are fully integrated in the control system. This is the only way to achieve absolute precision and microsecond synchronization between all automation components, including machine vision. The system can be connected with an axis in just a few clicks.

- Reproducible images for reproducible results

- Minimum FOV (field of view) necessary

- Razor-sharp images at high speed

Precalibrated for fast commissioning and service

B&R calibrates all lighting elements and optical systems – consisting of lens, sensor and focus adjustment – prior to delivery. As a result, there are no parameter or programming changes required when devices are exchanged in the field.

The system behaves in the same way every day—no matter if you install the camera yesterday, today, or tomorrow. In the event of service, machine downtimes are reduced to a minimum. This also accelerates commissioning times for series-built machines.

- Improved repeat precision by 10x or more

- Minimum downtime in event of service

- Increased OEE

- Reduced TCO

High-speed objects perfectly illuminated

Each light has an integrated flash controller, so no external hardware is required. The controller ensures a precise pulse current supply to the powerful LEDs: Already with a pulse duration of 1 µs, the light reaches 100% intensity.

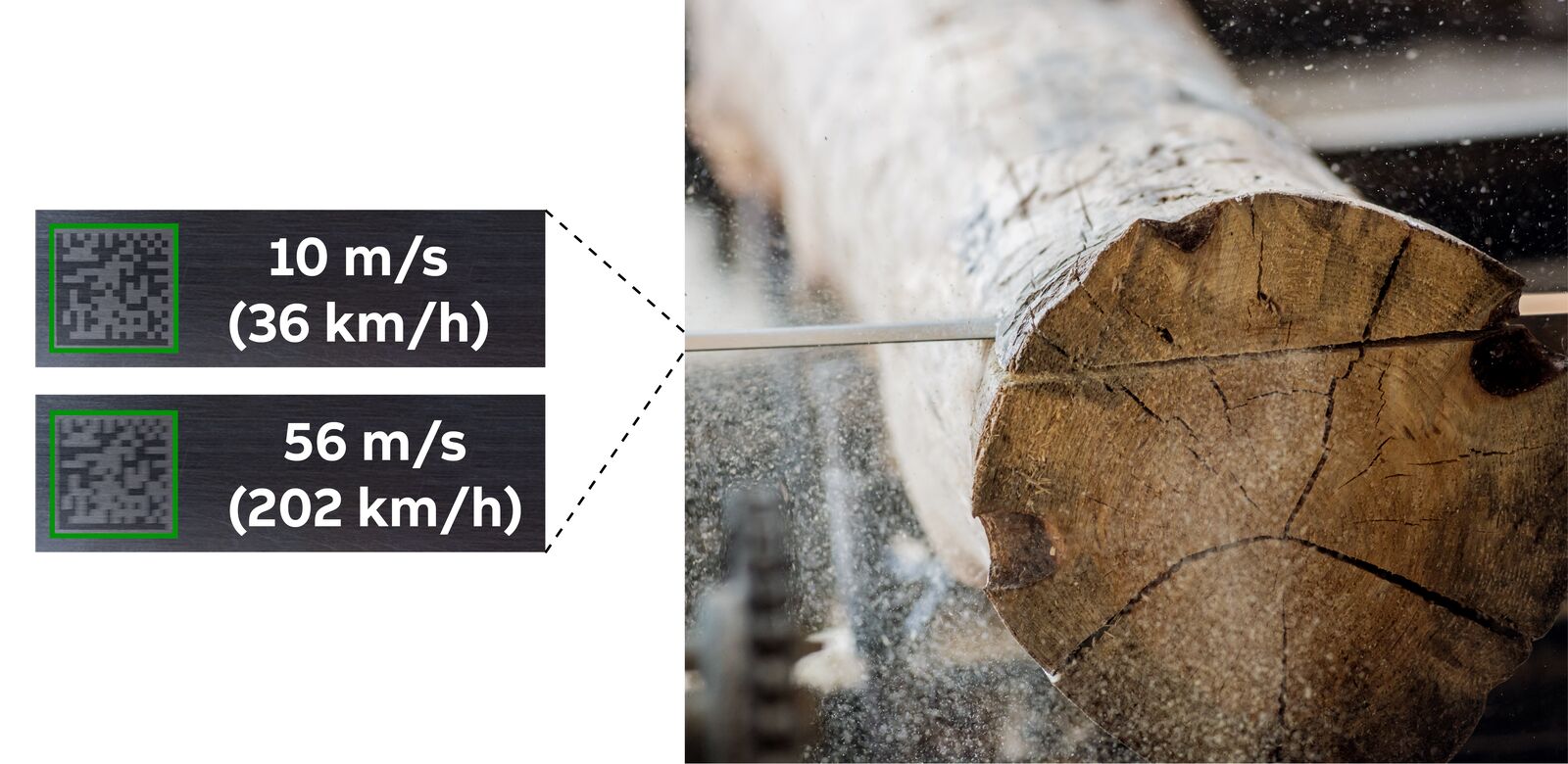

Unlike conventional image processing systems, the B&R vision system can therefore also be used in high-speed applications without any problems. We recently realized an application where the system reads a data matrix code on a band saw blade at 56 m/s speed. Also, the high-performance lighting eliminates almost entirely the influence of extraneous light - a crucial quality factor.

- Maximum intensity and homogeneity

- No chance for extraneous light

- Automatic adaption to every situation

- Repeatable intensity due to factory calibration

Both the hardware and software of B&R's vision solution are fully integrated in the control system. This is the only way to achieve absolute precision and microsecond synchronization between all automation components – including machine vision. With only one engineering tool and one application to manage, controls engineers will now be able to implement many machine vision tasks on their own.